Front axle articulation

The pendulum joint gives the vehicle high tipping stability.

The position of the pendulum joint allows the front axle an extremely large pendulum travel.

Let us advise you today!

Write us. Without obligation.

Powerful engine - economical consumption

The 4-cylinder Kohler engine in a very compact design features

a speed-independent controlled common rail high-pressure injection system as well as a fully electronic engine control. This means that the SAUERBURGER GRIP 4 always drives at the economic optimum and is extremely fuel-efficient. With its 2.5 litre displacement, the 4-cylinder engine is characterised by effervescence and dynamism, as well as smooth running and high performance.

Technical solutions

Can-Bus-gesteuerte Fahrzeugelektronik

Reinigung einfach zugänglich

Kat II mit bis zu 1450 kg Hubkraft

Kat II mit bis zu 1500 kg Hubkraft

Der Abgasstrom zieht die warme Luft vom Motorrinnenraum ins Freie

Economical driving with state-of-the-art engine management

The SAUERBURGER GRIP4 has 4 different driving modes. These ensure the optimum driving programme for every application. The tractor electronics control the diesel engine speed in accordance with the power requested by the hydrostat for the travel drive or the PTO drive.

1. automotive control

The speed and engine revolutions of the vehicle are controlled via the foot accelerator pedal.

2. travel lever control field

The engine/power take-off speed is set via a separate "encoder" control element and the speed is controlled via the travel lever.

3. road control lever

The engine speed is controlled via the foot throttle and the speed via the driving lever.

4. accelerator pedal control field

The engine speed/power take-off speed is set via the "encoder" and the driving speed via the foot pedal.

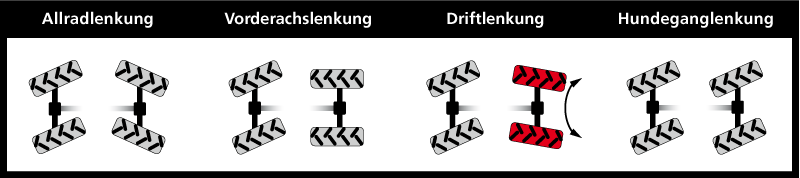

Steering modes

Its hydraulic all-wheel steering with four steering options enables very good manoeuvrability.

In drift steering, the axles are controlled independently of each other. The front axle via the steering wheel and the rear axle via the joystick.

Technical details

Motor

- 4-cylinder-Turbo-Motor Kohler KDI 2504

- 55 kW / 75 hp at 2600 rpm according to ECE R 24

- Max. Torque 315 Nm at 1500 rpm

- Common-Rail

- electr. Direct injection with 2.5 l displacement

- Exhaust gas stage V, water-cooled, charge air-cooled

Gearbox

- Infinitely variable hydrostatic travel drive via axial piston variable displacement pump

- Stepless hydraulic motor with downstream 2-speed gearbox

- Standard all-wheel drive with disengageable and engageable front axle

Speeds

- Terrain 0-20 km/h

- Road 0-40 km/h

Axis drive

- Planetary final drive

- 100% hydraulically operated differential lock

- Disc brakes running in an oil bath

Driver's platform

- Dust-tight full-view comfort cabin

- vibration and noise damped

- with safety frame (tested according to 79/622/EEC)

- Side door that can be opened

- Curved and hinged rear window

- Heating

- Air conditioning

- Power connection via cigarette lighter

- Optional:

- Glass door with pivot window

Front hydraulics

3-point CAT. II: max. Lifting force

1500 kg at 180 bar

Hydraulic lateral displacement

360 mm

Vibration damping for road travel autom. activatable

Relief control infinitely adjustable

Rear hydraulics

Rear power lift with Walterscheid quick coupling KAT. II:max. Lifting force

1450 kg at 180 bar

Working hydraulics

Gear pump

30 l/min at 180 bar

Optional:Axial piston variable displacement pump

60 l/min at 180 bar

PTO

Front PTO

1000 rpm

Direction of rotation in the direction of travel:

clockwise

Rear PTO

540 rpm

Direction of rotation in the direction of travel:

clockwise

Dimensions

Inside turning circle

3003 mmm

Vehicle dimensions

see illustrations

Weight

Empty weight

2.800 kg

Permissible front axle load

3.000 kg

Permissible rear axle load

3.000 kg

Permissible total weight

4.700 kg

Trailer load unbraked max.

2.500 kg

Trailer load with overrun brakes

8.000 kg

With tyres 33x15.50-15 from BKT