Shredder ALBATROS

The machines from the SAUERBURGER – Mulcher – Production “Made in Germany” are designed for highest area performances. All plant residues, whether corn, straw, millet or green manure, are chopped extremely short, not only cutting the stems but also shredding them. This promotes rapid decomposition and humus formation, effectively helping to improve arable soils. Pests such as corn borers, which overwinter in the plants, are also intensively controlled.

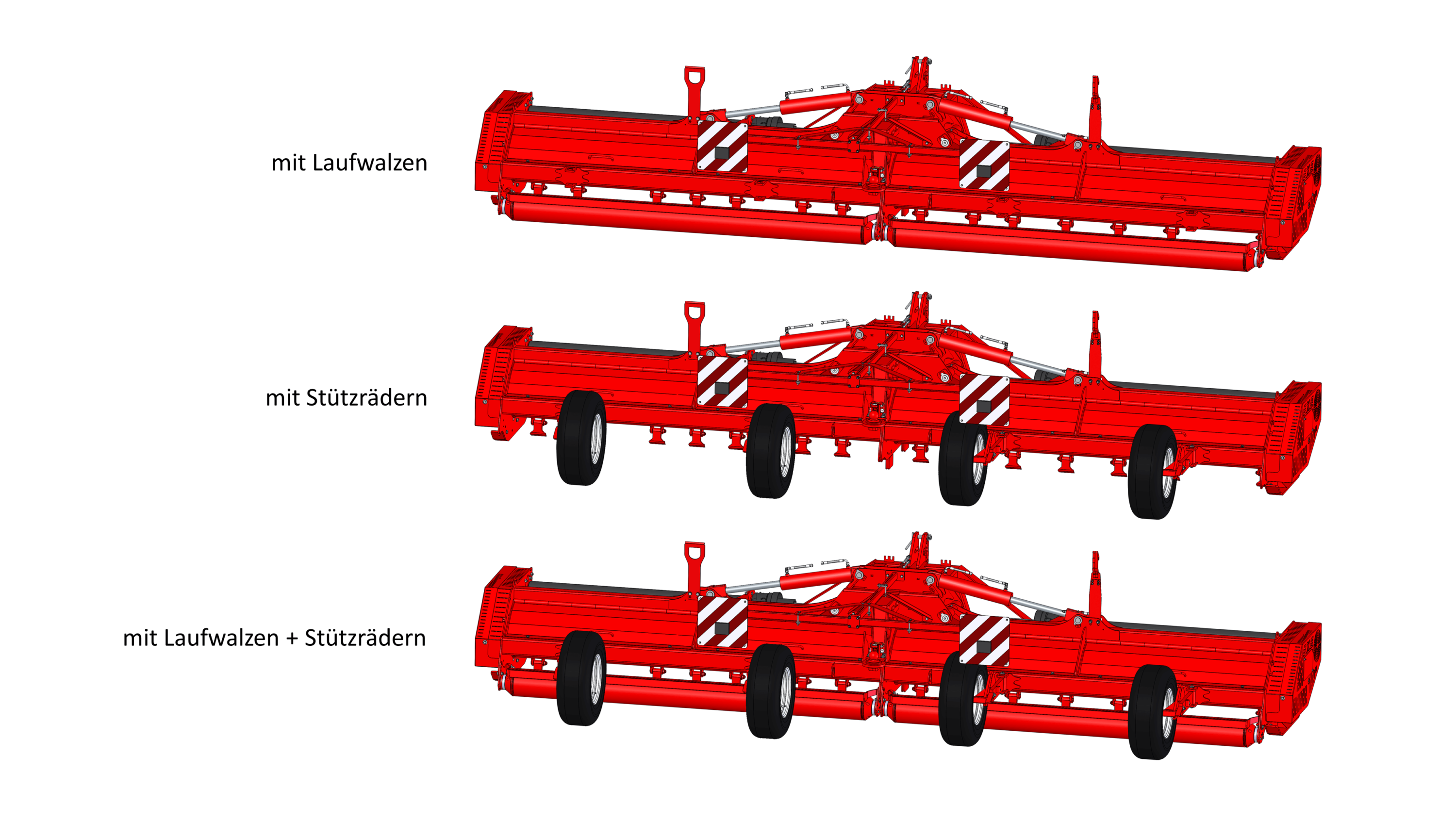

The shredders have a high inlet opening, as well as a particularly sophisticated shape of the housing, which is wedge-shaped in order to achieve the best shredding effect and large area output. This is also helped by the large rotor diameter with the specially shaped tools. The shredded material is distributed evenly over a wide area and can be incorporated without difficulty. Inside the housing there are counter-blades which contribute to a high crushing effect. The depth control of the machines is adjusted via support roller (copies uneven ground better) or on request with large support wheels. A robust gearbox and large-dimension V-belt drives with automatic tensioning devices transmit the drive force to the rotor shaft. To reduce wear in stony soils or high area outputs, additional baffle plates can be optionally installed in the housing. They form a buffer between the rotor and the housing and can be replaced after appropriate wear.

The newly designed ALBATROS models with working widths of 6.40 m and 7.20 m can be folded up in the middle for transport. This is done hydraulically, without dismounting, from the tractor, and the transport lock also locks or unlocks automatically. These machines are designed for enormous acreage outputs and intensive use, e.g. by contractors. They are built sturdy and very torsion resistant and are hitched very short behind the tractor. This minimizes the load on the three-point hydraulic system and relieves the front axle.

The working widths of the SAUERBURGER shredders are especially adapted to the common row spacings in maize cultivation. Excellent short chop quality is especially important for these crops. Keyword: rapid decay and control of pests.

The economical use of these machines is ensured by the stable and robust designs, large-dimension drives and bearings, maintenance-friendly accessibility and the highest quality of wear parts made of heat-treated steel.

The experience of 40 years of production of mulchers and shredders at SAUERBURGER benefit these machines and their users.

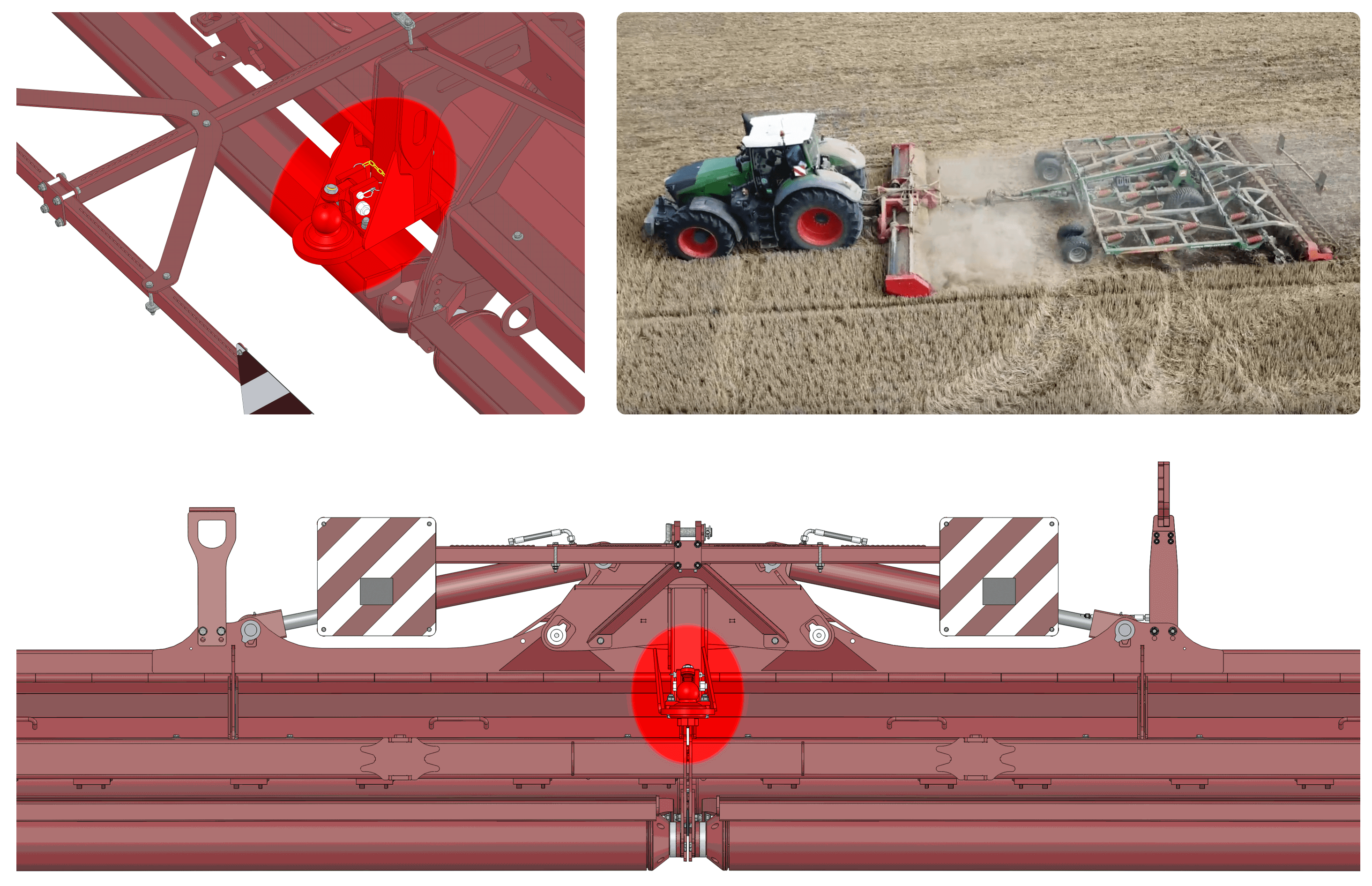

Transport

The Albatros can be folded up hydraulically in the middle for transport without having to leave the vehicle. The hydraulic transport lock also locks or unlocks automatically.

Robust drive

A robust gearbox and large-dimension V-belt drives with automatic tensioning devices transmit the drive force to the rotor shaft.

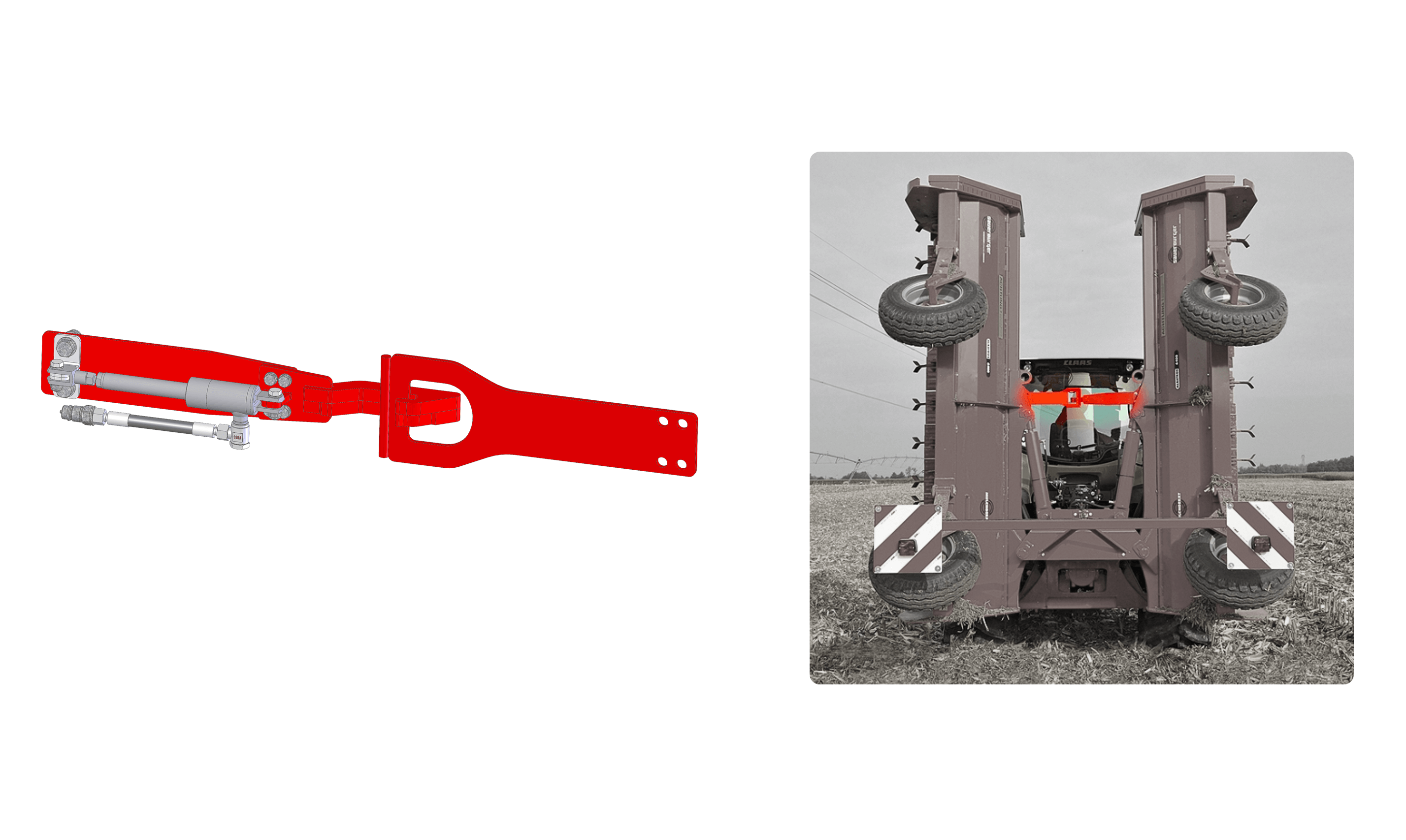

Optional: Ball head hitch K80

To work more efficiently, a ball hitch can be intigrated on the ALBATROS. This means that mulching can be carried out directly in one operation, followed, for example, by soil cultivation.

Video:

Sauerburg chipper ALBATROS 7200 in combination with

Fendt 1046 and Amazone Cennius 7000

ALBATROS 6400 | ALBATROS 7200 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Legend: *Corn flails **Y-flail ***Wide flails | ||||||||||

Working width | 6,40 m | 7,20 m | ||||||||

Transport height | 3,51 m | 3,91 m | ||||||||

Transport width | 2,87 m | 2,87 m | ||||||||

PTO speed | 1000 rpm | 1000 rpm | ||||||||

Number of V-belts | 6+6 XPB PRO | 6+6 XPB PRO | ||||||||

Number of tools | 160*/168**/56*** | 180*/192**/64*** | ||||||||

Power requirement | 132 kW/180 hp | 147 kW/200 hp | ||||||||

Weight | 3.450 kg | 3.960 kg | ||||||||