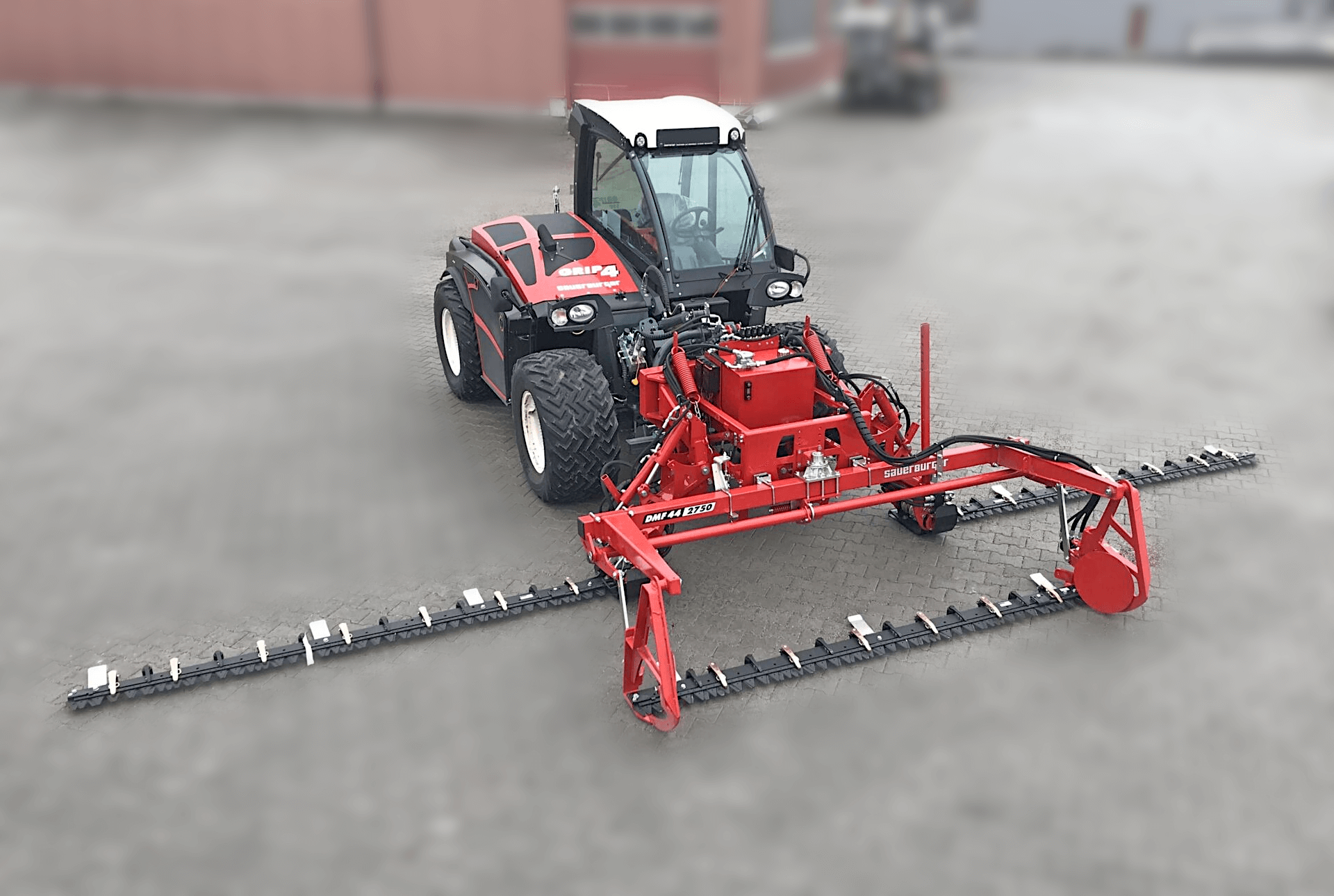

Double blade mower DM Butterfly

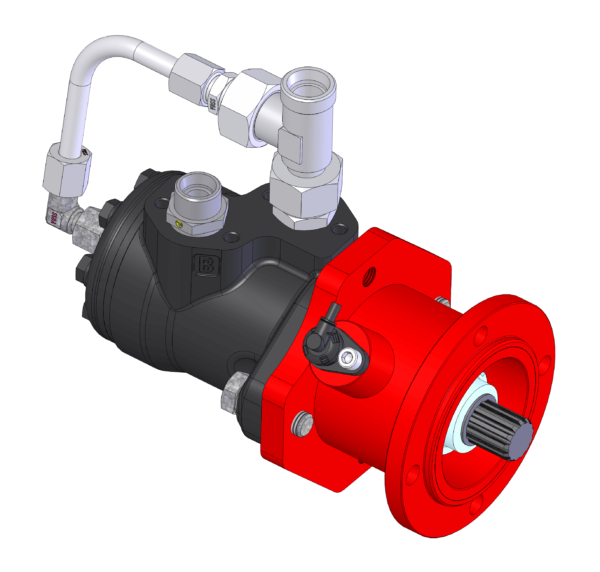

The SAUERBURGER DM Butterfly mower combinations are designed for high area outputs with relatively low power requirements. Due to the low power-to-weight ratio, the mower combinations can also be operated on vehicles with a power output of 70 hp or more. The ease of movement of the mowers, the low power consumption and the resulting fuel savings enable a very economical and ecologically valuable mode of operation.

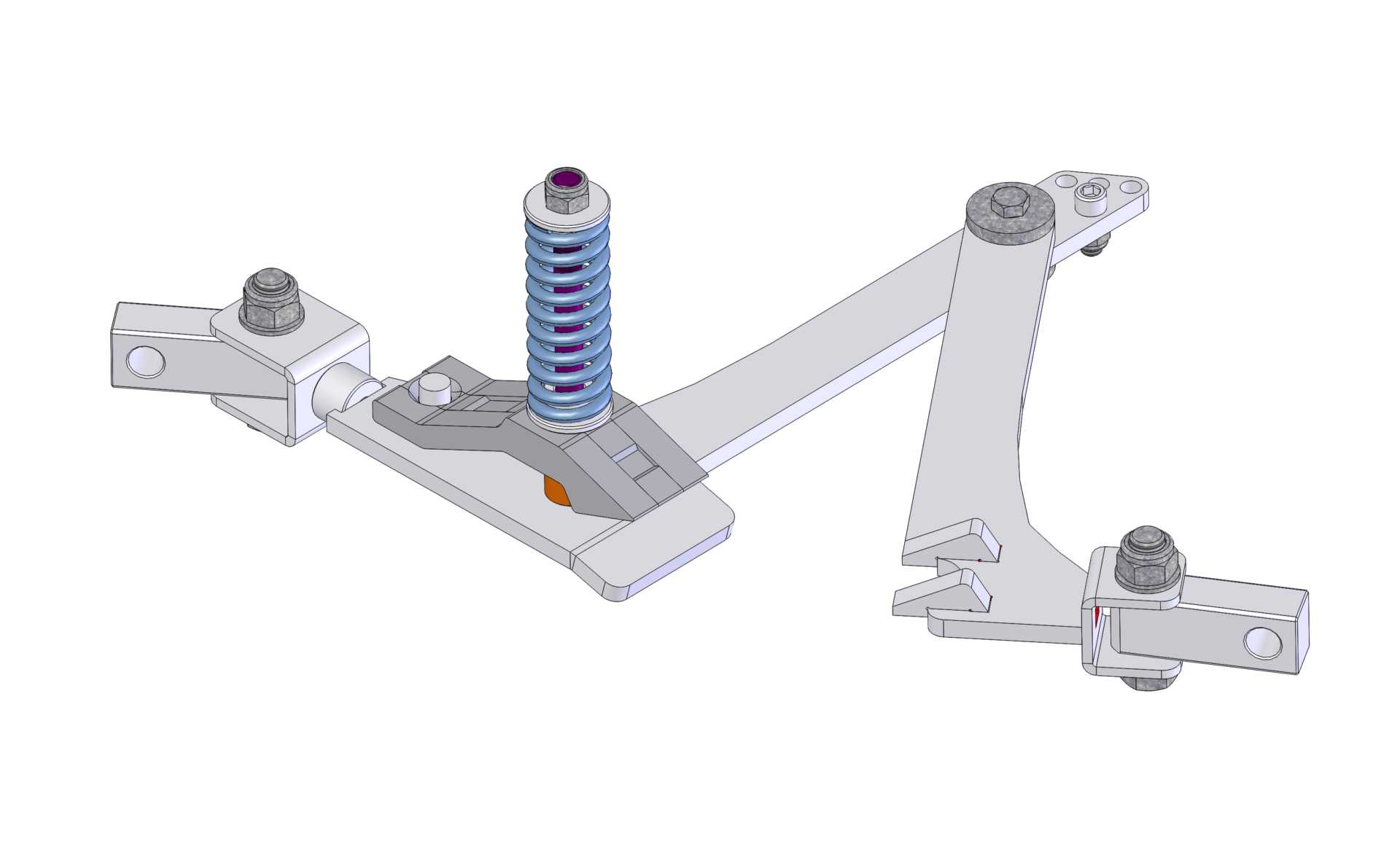

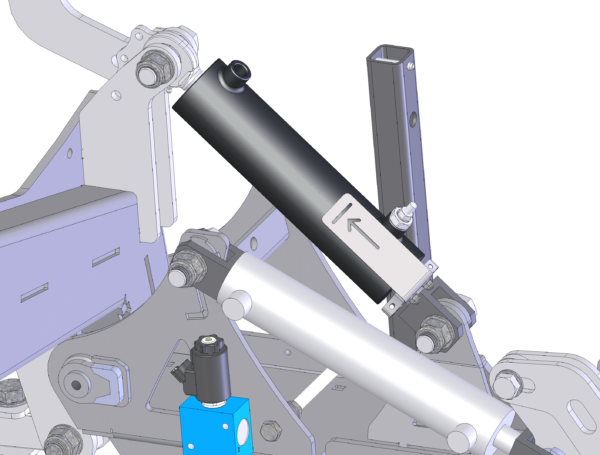

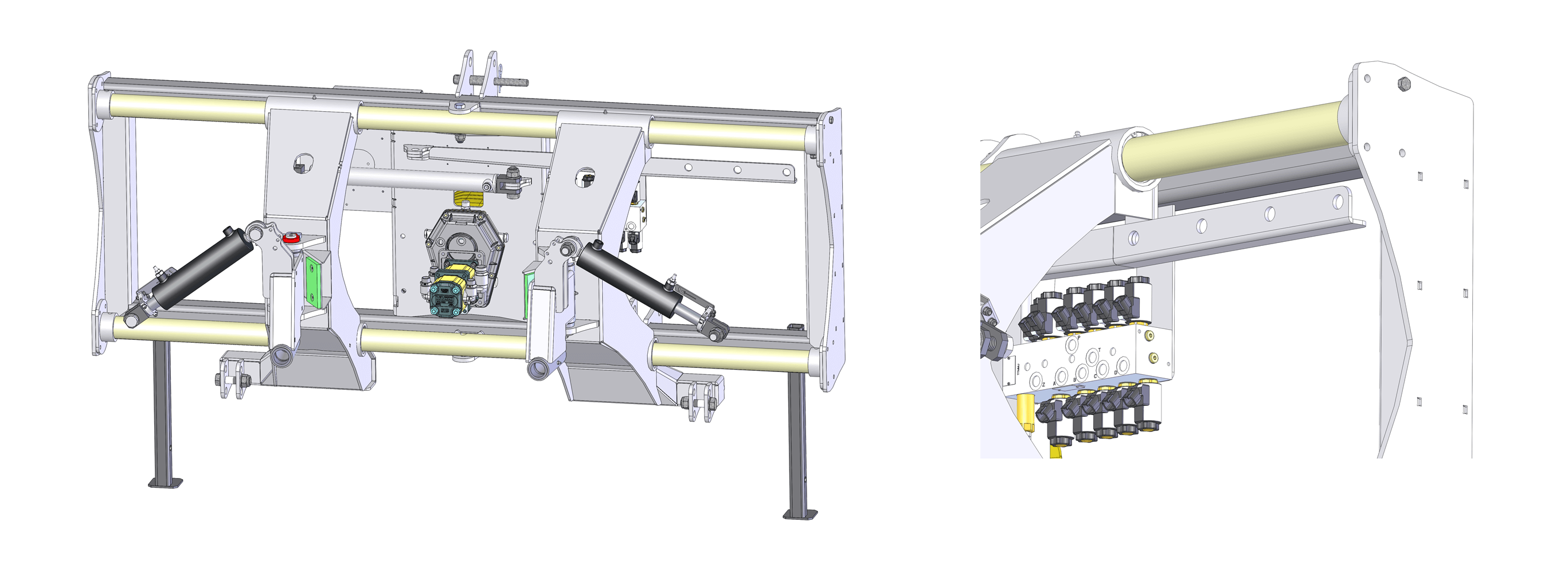

In the mower combinations, all cutterbars are mounted independently on the frame, which enables optimum ground hugging, even in cropped terrain.

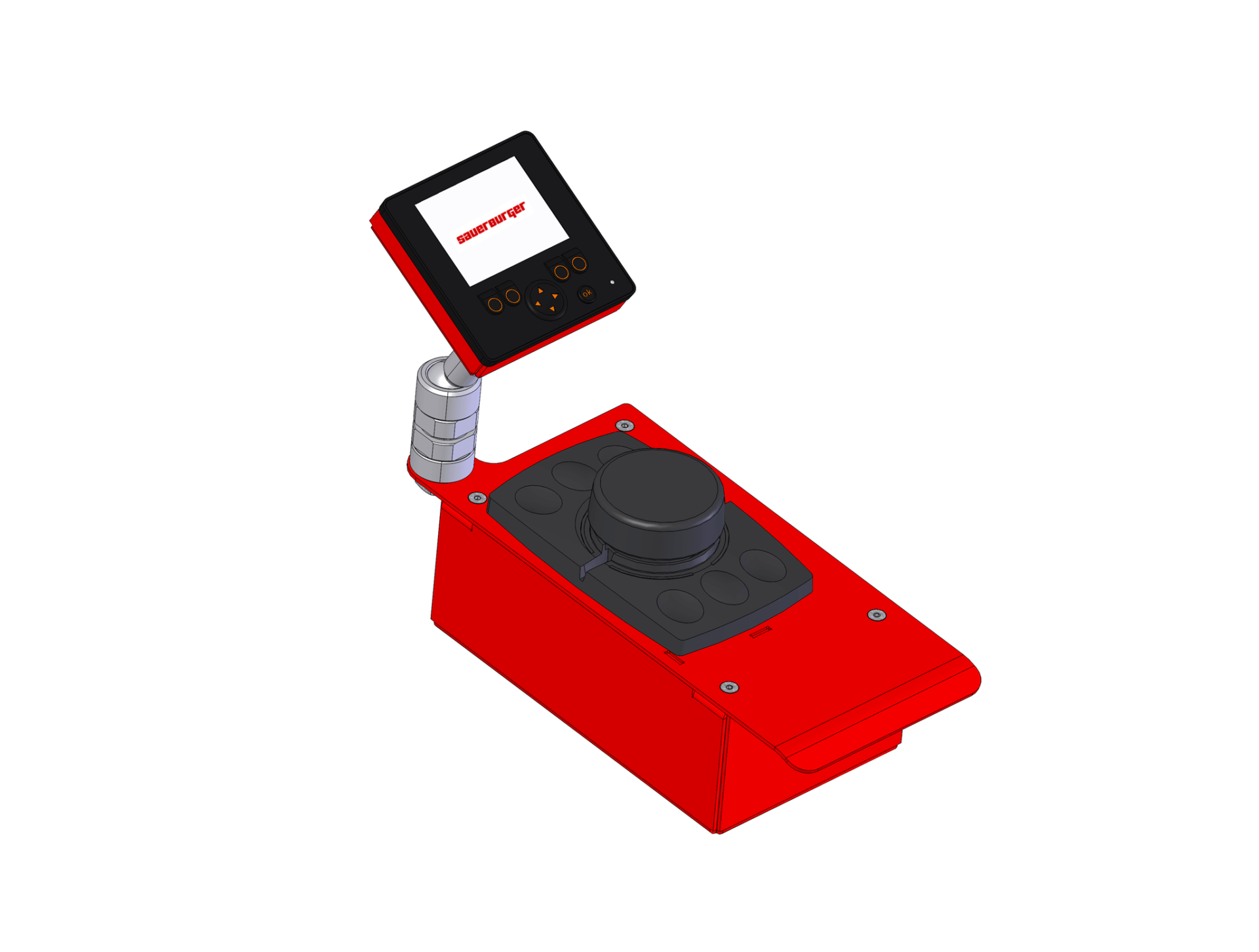

The drive speeds are monitored digitally and the cutterbars are operated via an operating terminal. In addition, the mowers have an automatic headland control, which makes operation easier.

The DM Butterfly is available as a front-mounted model or in the resolved version in front and rear-mounted versions.

Double blades are gentle on the insects

The double blade technology meets the demands for an environmentally and insect-friendly mowing technique for all green and nature conservation areas. The gentle shear cut and the gentle depositing of the forage (clippings) behind the cutter bar ensure maximum protection for all living creatures. With the appropriate cutting height, even ground-nesting birds are not endangered.

The neatly cut plant stems reduce the bleeding of the cuts and thus favour regrowth.

The wide, even crop placement also improves the drying process, which is why tedding (turning) of the crop can be reduced.

The gentle, non-rotating cut of the double knife does not spread dirt in the crop, resulting in significantly less forage contamination.

Variable application possibilities

Technical solutions

Typ | DM 7300 | DM 8000 | DM 9100 | DM 10000 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

Legend: *Split Ausführung **Front version | ||||||||||

Arbeitsbreite gesamt | 7,30 m | 8,00 m | 9,10 m | 10,00 m | ||||||

Working width outrigger | 2,40 m | 2,75 m | 3,36 m | 3,75 m | ||||||

Working width front mower | 2,75 m | 2,75 m | 2,75 m | 2,75 m | ||||||

Transport height | 2,88 m | 3,22 m | 3,82 m | 4,20 m | ||||||

Transport width | 3,0 m | 3,0 m | 3,0 m | 3,0 m | ||||||

Anzahl Laufsohlen | 12 pcs | 12 pcs | 12 pcs | 12 pcs | ||||||

Weight | 680 kg * resp. 1080 kg** | 700 kg * resp. 1100 kg** | 740 kg * resp. 1140 kg** | 760 kg * resp. 1160 kg** | ||||||